計量稱(cheng)重是(shi)一個動態非線性(xing)振動結構系統

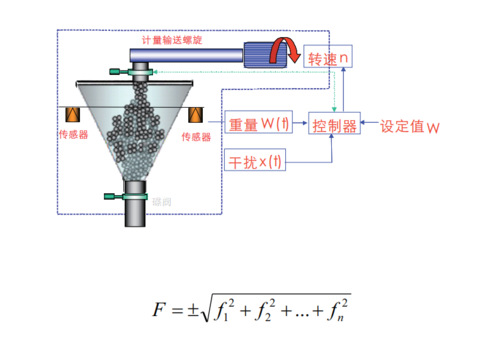

由圖所示, 計量稱重是(shi)有一組相(xiang)互影響的(de)部件組成(cheng)(cheng): a) 喂料裝(zhuang)置(螺旋機) b) 稱斗和傳感器. 它們組成(cheng)(cheng)一個(ge)動態的(de)非(fei)線(xian)性(xing)振動系(xi)統(tong)(tong)(tong). 所以(yi)計量的(de)精(jing)度是(shi)這一相(xiang)互作用(yong)系(xi)統(tong)(tong)(tong)在外(wai)界干擾的(de)作用(yong)下的(de)統(tong)(tong)(tong)計描(miao)述. 該(gai)系(xi)統(tong)(tong)(tong)是(shi)一反饋控(kong)制系(xi)統(tong)(tong)(tong). 計量系(xi)統(tong)(tong)(tong)的(de)誤(wu)差主要和以(yi)下因(yin)素有關(guan):

通常人們誤認為傳感器(qi)的精度(du)就是系(xi)統(tong)的精度(du). 還有片面強調靜態精度(du). 良好合理的電子秤(cheng)(cheng)計(ji)(ji)量(liang)系(xi)統(tong)是一個傳感器(qi)和喂料(liao)器(qi)組(zu)成的反饋系(xi)統(tong). 如圖所(suo)示, 除外界(jie)干擾(rao)信號(hao)外, 還必須考慮系(xi)統(tong)的自振(zhen)特性(xing)(xing). 系(xi)統(tong)的自振(zhen)特性(xing)(xing)和稱斗及支(zhi)撐(cheng)結構的設計(ji)(ji)密切相(xiang)關, 它主要是(質(zhi)量(liang), 彈(dan)性(xing)(xing)和阻尼)的函(han)數(shu). 由于設計(ji)(ji)的不同, 故會(hui)產生眾所(suo)周知的如秤(cheng)(cheng)斗的震動(dong)會(hui)造(zao)成秤(cheng)(cheng)重儀表數(shu)字的跳動(dong),這樣會(hui)影響(xiang)計(ji)(ji)量(liang)的精度(du)。當物(wu)料(liao)在加入(ru)的過程(cheng)中,會(hui)由于秤(cheng)(cheng)斗的震動(dong)或干擾(rao)等(deng)原因造(zao)成數(shu)值的不準確(que)。數(shu)值越偏離設定值,越影響(xiang)產品(pin)的質(zhi)量(liang)。采(cai)用和物(wu)流(liu)特性(xing)(xing)相(xiang)關的設計(ji)(ji)經驗, 開(kai)發動(dong)態配料(liao)算法,使秤(cheng)(cheng)重配料(liao)更加合理,誤差小,可靠性(xing)(xing)更高。

添(tian)加劑自(zi)動計量站

添(tian)(tian)加(jia)劑(ji)計(ji)量站可(ke)以靈(ling)活地(di)放(fang)置(zhi)在任(ren)何平臺或地(di)面上, 非常便于(yu)管(guan)理(li). 同(tong)時(shi), 擴充性能良好, 可(ke)以擴充添(tian)(tian)加(jia)劑(ji)加(jia)料斗(dou)(dou)(dou)(至8個). 計(ji)量好的添(tian)(tian)加(jia)劑(ji)進入一密相氣力輸送(song)(song)系統, 輸送(song)(song)至稱(cheng)斗(dou)(dou)(dou)或混合機. 添(tian)(tian)加(jia)劑(ji)加(jia)料斗(dou)(dou)(dou)配置(zhi)中(zhong)央負壓風(feng)機, 每(mei)個斗(dou)(dou)(dou)配置(zhi)獨立的脈沖除塵器.

采用添(tian)加劑(ji)計量站, 免去了繁雜的(de)將添(tian)加劑(ji)電葫(hu)蘆提升至塔樓的(de)過程.

計量采(cai)用(yong)亨(heng)維的精(jing)密計量輸送螺(luo)旋機帶集成開關閥, 螺(luo)旋葉片變螺(luo)距(ju), 出口配置均化輪. 具備清理(li)口. 驅(qu)動采(cai)用(yong)硬齒面(mian)法蘭連接減(jian)速機. 結構(gou)緊湊.