羥丙基(ji)甲級(ji)纖(xian)維素 HPMC

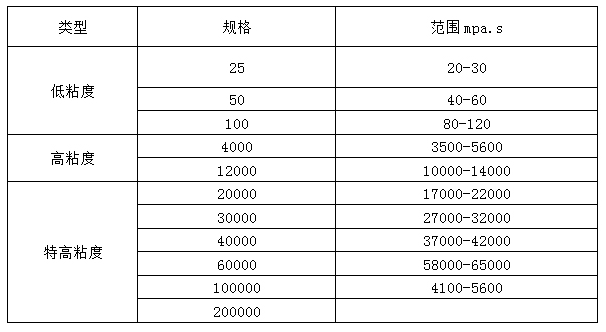

粘(zhan)度規格

注;粘度數值為(wei)2%水溶液20℃時的粘度

1%水溶液20℃時的(de)粘度。

另外還可根據用戶不同粘度(du)要求,滿足相應需求。

理化性質:

1. 外觀:白(bai)色或類白(bai)色粉(fen)末。

2. 顆粒(li)度:80目通(tong)過(guo)(guo)率(lv)(lv)為100%;100目通(tong)過(guo)(guo)率(lv)(lv)大于99.5%。

3. 炭化溫(wen)度(du):280-300℃。

4. 視密(mi)度:0.25-0.70g/cm3(通(tong)常在0.5g/cm3左右(you)),比重1.26-1.31。

5. 變色溫度(du):190-200℃。

6. 表面張力:2%水溶(rong)液為42-56dyn/cn。

7. 溶(rong)(rong)解(jie)性(xing)能(neng):溶(rong)(rong)于水及部分有機溶(rong)(rong)劑、如適當比例的乙(yi)醇/水、二氧(yang)乙(yi)烷等。水溶(rong)(rong)液具(ju)有表(biao)面活性(xing)。透明度(du)(du)(du)高,性(xing)能(neng)穩定,不(bu)(bu)同(tong)規(gui)格(ge)的產品凝膠溫(wen)度(du)(du)(du)不(bu)(bu)同(tong),溶(rong)(rong)解(jie)度(du)(du)(du)隨(sui)粘(zhan)度(du)(du)(du)而變化,粘(zhan)度(du)(du)(du)愈低,溶(rong)(rong)解(jie)度(du)(du)(du)愈大,不(bu)(bu)同(tong)規(gui)格(ge)HPMC其性(xing)能(neng)有一定差異,HPMC在(zai)水中的溶(rong)(rong)解(jie)不(bu)(bu)受PH值影響。

8. HPMC隨(sui)甲氧基含量減(jian)少(shao),凝(ning)膠(jiao)點(dian)升高,水(shui)溶(rong)解(jie)度下(xia)降,表面活性(xing)也下(xia)降。

9. HPMC還具有增稠能力,排鹽(yan)性(xing)、低灰份(fen)、酸堿(jian)穩定性(xing)、保(bao)水(shui)性(xing)、尺寸(cun)穩定性(xing)、尺寸(cun)穩定性(xing)、優良的(de)成膜性(xing)、以及廣泛的(de)耐(nai)酶性(xing)、分散性(xing)和粘結性(xing)等特點。

主要用途:

本(ben)產品(pin)(pin)(pin)為(wei)工(gong)(gong)(gong)(gong)業(ye)級HPMC,主(zhu)要(yao)用(yong)(yong)(yong)(yong)(yong)途為(wei)聚(ju)氯乙烯生產中(zhong)坐分散劑(ji)(ji)(ji),系(xi)懸浮聚(ju)合制備PVC主(zhu)要(yao)助劑(ji)(ji)(ji)。另外(wai)在(zai)石油化工(gong)(gong)(gong)(gong)、建(jian)材(cai)、除漆劑(ji)(ji)(ji)、農(nong)業(ye)化學品(pin)(pin)(pin)、油墨(mo)、紡織(zhi)印染(ran)、陶瓷、造(zao)紙(zhi)、化妝品(pin)(pin)(pin)等產品(pin)(pin)(pin)生產中(zhong)做增(zeng)稠劑(ji)(ji)(ji)、穩定劑(ji)(ji)(ji)、乳化劑(ji)(ji)(ji)、賦形劑(ji)(ji)(ji)、保(bao)水劑(ji)(ji)(ji)、成(cheng)膜劑(ji)(ji)(ji)等。在(zai)合成(cheng)樹脂方面的應用(yong)(yong)(yong)(yong)(yong),可(ke)(ke)使獲得的產品(pin)(pin)(pin)具有顆料規整、疏松、視比(bi)重(zhong)適宜,加工(gong)(gong)(gong)(gong)性(xing)(xing)能(neng)優良等特(te)點,從(cong)而(er)基本(ben)上取代了明膠和聚(ju)乙烯醇做分散劑(ji)(ji)(ji)。另外(wai)在(zai)建(jian)筑工(gong)(gong)(gong)(gong)業(ye)施工(gong)(gong)(gong)(gong)過(guo)程(cheng)中(zhong),主(zhu)要(yao)用(yong)(yong)(yong)(yong)(yong)于砌(qi)墻(qiang),灰泥(ni)粉(fen)飾(shi)(shi)(shi),嵌縫等機械化施工(gong)(gong)(gong)(gong)中(zhong);特(te)別在(zai)裝飾(shi)(shi)(shi)性(xing)(xing)施工(gong)(gong)(gong)(gong)中(zhong),用(yong)(yong)(yong)(yong)(yong)作粘貼(tie)磁磚,大理石,塑(su)料裝飾(shi)(shi)(shi),粘貼(tie)強度高(gao),還(huan)可(ke)(ke)以減(jian)少水泥(ni)用(yong)(yong)(yong)(yong)(yong)量。用(yong)(yong)(yong)(yong)(yong)于涂(tu)料行業(ye)中(zhong)的作增(zeng)稠劑(ji)(ji)(ji),可(ke)(ke)是涂(tu)層光亮細膩,不脫(tuo)粉(fen),改善流平(ping)性(xing)(xing)能(neng)等。用(yong)(yong)(yong)(yong)(yong)于粉(fen)刷石膏、粘結石膏、嵌縫石膏、耐水膩子(zi)中(zhong)可(ke)(ke)顯著提(ti)高(gao)其保(bao)水性(xing)(xing),粘結強度等。還(huan)可(ke)(ke)用(yong)(yong)(yong)(yong)(yong)于功能(neng)陶瓷、冶金(jin)、種(zhong)子(zi)包衣(yi)劑(ji)(ji)(ji)、水性(xing)(xing)油墨(mo)、化妝品(pin)(pin)(pin)、電(dian)子(zi)、印染(ran)、造(zao)紙(zhi)等領域。

溶解方法:

1、取所(suo)需數量(liang)的熱水,放入(ru)容器中(zhong)加(jia)熱至85℃以(yi)上(shang),在慢(man)慢(man)攪拌下逐漸(jian)加(jia)入(ru)本品,纖維素(su)起(qi)初浮(fu)在水面上(shang),但逐漸(jian)被水分散,形(xing)成均勻的淤漿(jiang),在攪拌下冷卻,直(zhi)到透明(ming)。

2、或者(zhe)將1/3--2/3的(de)(de)水加熱(re)至85℃以上,加入(ru)(ru)纖維(wei)素,得(de)到(dao)(dao)熱(re)水漿(jiang)料(liao),再加入(ru)(ru)剩余量的(de)(de)冷水,保持攪拌,冷卻(que)至20℃左右得(de)到(dao)(dao)的(de)(de)混合(he)物即成。

3、纖維素目數較(jiao)細,在(zai)(zai)攪(jiao)拌均勻的(de)粉(fen)體中為單獨的(de)小微粒存在(zai)(zai),遇水(shui)后即迅速溶解,形成所需粘度。

4、或在常溫下將(jiang)纖(xian)維素(su)緩慢均勻(yun)的加入(ru),加入(ru)過程中要不停攪拌,直至形成透(tou)明溶(rong)液。

包裝、貯運注意事項:

涂塑(su)的(de)聚(ju)丙(bing)烯編(bian)織袋(dai)或內襯(chen)聚(ju)乙(yi)烯薄膜內袋(dai)的(de)紙(zhi)板桶(tong)封裝,每袋(dai)(桶(tong))凈重:25.0kg。

在貯藏及運輸(shu)過程中防止日(ri)曬雨淋(lin)并防潮。